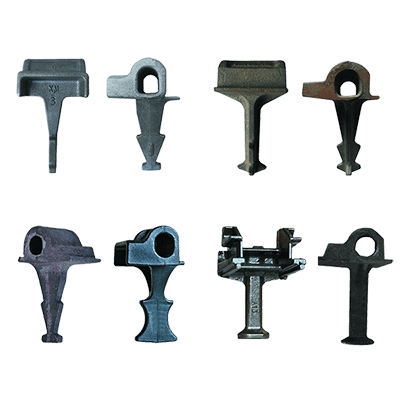

The rail shoulder is embedded in concrete at the time of casting, it’s used to grips the clip effectively and provides lateral support to rail. It can be divided into two kinds, Cast-in rail shoulder and Weld-on rail shoulder.

Cast-in rail shoulder

The casting shoulder is pressed in concrete sleeper and assembled with E clip in order to fasten the rail. The material we use is cast iron and the mechanical property and chemical composition of the rail cast iron shoulder are shown below:

Technical Properties:

| Material | QT500-7 | QT450-10 | QT400-15 |

|---|---|---|---|

| Tensile Strength | ≥500 Mpa | ≥450 Mpa | ≥400 Mpa |

| Yield Strength | ≥320 Mpa | ≥310 Mpa | ≥250 Mpa |

| Elongation | ≥7 | ≥10 | ≥15 |

| Hardness | 170~230HB | 160~210HB | 130~180HB |

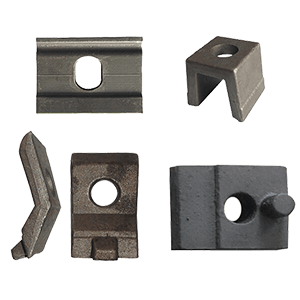

Weld-on rail shoulder

Features:

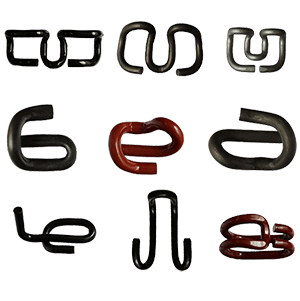

1. Designed for use with E style elastic rail clips, the weld on shoulder fastening allows customers to fabricate rail retaining units on both steel sleepers and steel base plates.

2. The rail cast iron shoulders can also be welded on to longer length steel sleeper sections or bearers for use in the fabrication of switch and crossing layouts where vertical rail geometry is employed. The railway shoulder’s ability to be welded in the specific position as dictated by the layout design makes it particularly useful and cost effective in this role.